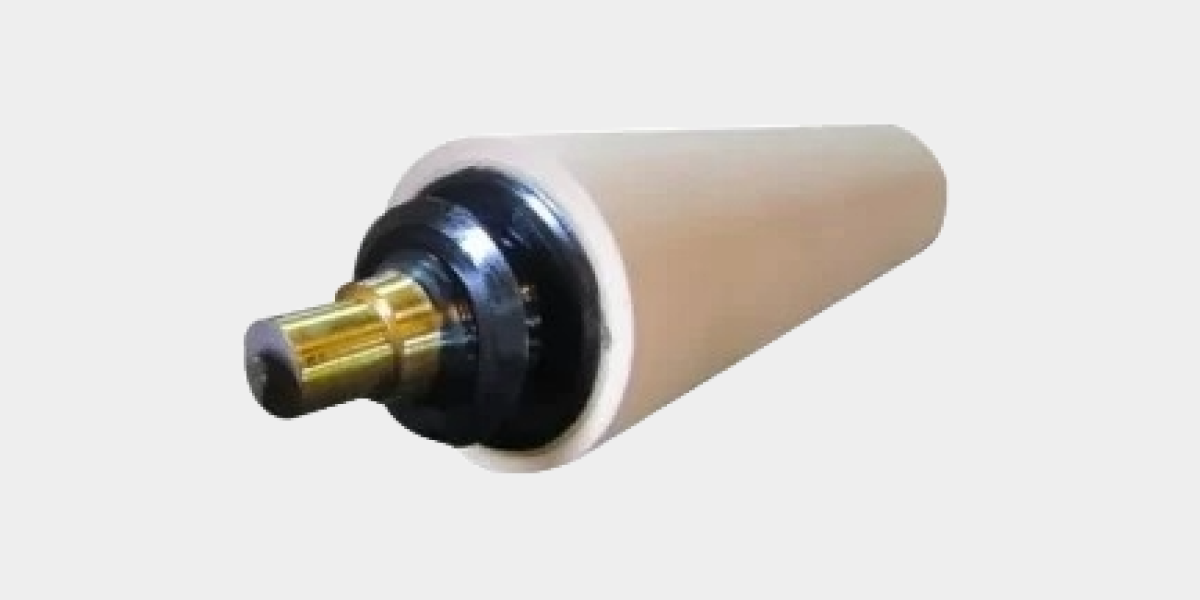

Mangle Squeeze Roller

In the processing sector of the textile and fabric industry, it is vital to treat the fabrics uniformly, maintain the moisture content and assure a uniform quality of fabric. The Mangle Squeeze Roller is one of the most important elements that contribute to these objectives. It is a roller that is designed to perform precision squeezing and the handling of fabrics in order to make significant contributions to dyeing, washing, finishing and chemical treatment processes.

This web text is in simple language that is easy to understand to enable manufacturers, technicians, and buyers to have a clear understanding of the importance, working, benefits and applications of a Mangle Squeeze Roller. The design is search engine friendly, business and appropriate to industrial sites.

Understanding the Purpose of a Mangle Squeeze Roller

A Mangle Squeeze Roller is a roller commonly employed in mangled textile to squeeze out any excess water, dye or chemical solution in a fabric. Its operation involves putting pressure through controlled pressure on the fabric when it passes through two rollers. This is done to make sure that the fabric retains the required amount of liquid.

The primary mission of a Mangle Squeeze Roller is to:

- ● Keep moisture levels even.

- ● Improve fabric quality

- ● Reduce chemical wastage

- ● Uniform processing leads to support.

Textile operations could be subject to uneven squeeze, damage of fabrics or poor finishing output without a well-constructed Mangle Squeeze Roller.

Why Mangle Squeeze Roller Is Important in Textile Industry

The clothing business requires precision and repetition. A Mangle Squeeze Roller would make sure that all meters of fabric are treated equally. This uniformity is essential in attainment of similar color shades, appropriate chemical penetration, and quality finish.

Important motives as to why Mangle Squeezer Roller is significant:

- ● Liquor pickup ratio control.

- ● Prevents fabric distortion

- ● Improves the quality of dyeing and finishing.

- ● Enhances industry performance.

Due to these benefits, Mangle Squeeze Roller has become a basic component of the modern textile processing lines.

How a Mangle Squeeze Roller Works

The design principle of a Mangle Squeeze Roller is not complicated. A piece of fabric is positioned in place between two rotating rollers that are controlled under pressure. Passing through the fabric surplus liquid is squeezed out uniformly.

Other key performance determinants are:

- ● Roller hardness

- ● Surface finish

- ● Pressure settings

- ● Fabric type

A properly designed Mangle Squeeze will guarantee proper movement of the fabrics and proper squeeze that will never create any damage or creases.

Mangle Squeeze Roller for Uniform Liquid Control

One of the largest benefits regarding the usage of Mangle Squeeze Roller is uniform liquid control. The roller is needed to provide uniform pick up through the fabric width regardless of whether it is dye, water or chemical solution.

This results in:

- ● Even dye shades

- ● Reduced reprocessing

- ● Better fabric appearance

- ● Lower operational costs

Mangle Squeeze Roller systems help the textile units to keep high quality levels.

Materials Used in Mangle Squeeze Roller Manufacturing

The materials are the key factor to the performance and durability of Mangle Squeeze Roller. Manufacturers choose materials depending on the operating conditions, the chemical exposure, and the load requirement.

Common materials include:

- ● Natural rubber

- ● Nitrile rubber

- ● EPDM rubber

- ● Polyurethane

The various materials have various advantages including chemical, elastic, heat, and wear resistance. The choice of the appropriate material guarantees the long service life and constant squeezing performance.

Design Features of a High-Quality Mangle Squeeze Roller

The Mangle Squeezer is a premium designed roller that will ensure high-quality results. Key design features include:

- ● Even surface finish to achieve even pressure.

- ● Strong core construction

- ● Proper tolerance of diameter.

- ● Vibration-free operation balanced structure.

- ● Great adhesion between rubber and core.

These advantages assist it to sustain the pressure in squeezing and avoid damage of the fabric during the continuous process.

Applications of Mangle Squeeze Roller

The Mangle Squeeze Roller enjoys a large customer base in the process of textile and fabric.

- Dyeing Process

Provides consistent dyeing and color.

- Washing Process

Ejects the water used in washing to enhance the drying process.

- Chemical Finishing

Regulates the absorption during finishing processes.

- Bleaching Process

Ensures constant elimination of liquid to achieve better bleaching.

The Mangle Squeeze Roller helps in handling the fabric in a smooth manner and its processing in every application.

Benefits of Using a Mangle Squeeze Roller

A high quality Mangle Squeeze Roller has a number of operational advantages:

- ● Squeezing the fabric in a uniform manner across the width.

- ● Better quality of fabrics and finish.

- ● Less chemical and water wastage.

- ● Amplified effectiveness in production.

- ● Reduced maintenance need.

- ● Long operational life

Due to such advantages, the textile producers would rather buy Roller products of knowledgeable suppliers such as Indian Roller Industries Pvt. Ltd.

Customization Options for Mangle Squeeze Roller

All processes in the textile industry have their own needs. A Mangle Squeeze Roller can be built to fit to a specific requirement including:

The Roller is an essential part of the industrial infrastructure of modern automation systems that cannot be replaced.

- ● Special roller diameter and length.

- ● Specific rubber hardness

- ● Compounds that are resistant to the special chemicals.

- ● Rough or grained finish of the surface.

- ● Designs with high-loads or high-speed.

Mangle Squeezer Solutions Mangle Squeezer Solutions Customized solutions of mangle squeezer can be used in improving the quality of output and process control.

Maintenance Tips for Mangle Squeeze Roller

A Mangle Squeeze Roller can be maintained over a long period of time.

The basic maintenance measures are:

- ● Frequent post-operative cleaning.

- ● Staying off sharp objects around the roller surface./li>

- ● Periodic alignment checks

- ● Sufficient storage in a dry environment.

- ● Replacement in time on the surface wears manifestation.

These actions assist in keeping the precision of the squeezer and avoid unwanted downtimes.

How to Choose the Right Mangle Squeeze Roller

In order to work optimally, one should select the right Mangle Squeezer Roller. Considerable factors to be taken into consideration are:

- ● Fabric type and thickness

- ● Liquid type that is squeezed.

- ● Operating temperature

- ● Machine speed

- ● Required pressure level

Talking to an expert roller manufacturer about this means that you have the Mangle Squeeze Roller exactly the way you need it in your process.

Quality Importance in Mangle Squeeze Roller Performance

A roller of poor quality may lead to an uneven squeeze, cloth impressions, and constant breakdowns. A properly made Mangle Squeeze Roller will have reliable pressure, uniformity of flow of fabric and the same results throughout operation over the long production runs.

Good rollers minimize rework, wastage and enhance efficiency of a plant.

Future Demand for Mangle Squeeze Roller

As the automated and high-speed textile machines continue to grow, there is a heightening demand in the advanced Mangle Squeeze Roller solutions. The contemporary rollers are made using better materials and precision engineering in accordance with the changing requirements of the industry.

The innovation in Roller technology will be influenced by energy efficiency, durability and regular performance.

Conclusion

Mangle Squeeze Roller is an essential element to the processing of textiles, which maintains a regulated removal of liquid, consistent treatment of the fabric and high quality production. This roller helps in efficient and reliable textile operations since it is used in dyeing and washing as well as chemical finishing.

The ability to ensure that the quality, wastage and long-term operational success of textile units can be attained by the correct choice of Mangle Squeezer rollers, proper maintenance, and a reliable manufacturer. An efficient Mangle Squeeze is not a simple machine component, but one of the major inputs to textile perfection.