Plot No. 62/2/1, Sahibabad, Ghaziabad, UP India

Wide range of PU, Rubber & Hard Chrome Plated Rollers for use in Steel Industries. Our Rollers are having all kinds of Acid, Temperature, and Abrasion Resistance. We undertake the following types of Rubber, PU, and Hard Chrome Plated Rollers.

Bridle Roller drive Strips through the Production line, are Rollers are different hardness ozone and abrasion resistance and will not degrade from oil and Corrosive material. Bridle roll is the important equipment in the continuous annealing line, whose main function is to divide the line into several sections according to the difference of the strip tension, and control the strip tension. The dynamical mechanism model of the strip tension in bridle roll is proposed in this paper.

Get a Quote

Applicator roller is used in metal sheet industries for galvanizing or color coating and chemical coating applications, Applicator roller likewise name roller is utilized to plunge paint and equally coat on to the metal strip surface, roller surface quality is straightforwardly connected to the metal strip surface. our applicator roller is high solvent resistance and high elongation.

Get a QuoteRollers are used to squeeze chemicals or water from steel strips to Keep liquids within the Immersion tank. the roller is able to Stands Swelling and withstands acids and alkalines. They are often made from rubber or polyurethane due to their flexibility, durability, and ability to provide uniform pressure without damaging the materials being processed. They are essential in operations like ink application in printing presses, coating processes, and during the shaping or drying of materials in textile production.

Get a Quote

Sink Rolls are made off with top-notch quality materials at our plant which are appropriately tried for their productivity and dependability. These rolls work in a destructive climate like liquid zinc, galvalume, galvanneal, lead, and aluminum so they are fabricated at high accuracy in light of international standards. These rolls can work under high temperatures and are impervious to consumption

Get a QuoteAccumulator rollers are used in film and metal handling lines. Our rollers are abrasion, tear, and corrosive resistant. The roller functions by providing a buffer or storage space for materials that need to be gathered and then released in a controlled manner. It helps to maintain consistent material flow, especially when there are interruptions or delays in downstream processes. The accumulator roller can also help manage tension and reduce material slippage, ensuring that the production line operates smoothly without disruptions.

Get a Quote

Pinch Roller threading tape at a precise speed by fenching. it is such a way that does not deform the tape. Pinch rollers are commonly used in printing presses, photocopiers, and textile machines. They are typically made of durable materials such as rubber or polyurethane, allowing for optimal grip without damaging the material being processed. The amount of pressure applied by the pinch roller can be adjusted depending on the material's thickness and sensitivity, providing control over material feeding, movement, and tension.

Get a QuoteSnubber rollers are small polyurethane-covered rollers used to hold a strip against a bridle roller. It is used in industrial processes to absorb or reduce vibrations, shock, and sudden movements in mechanical systems, particularly in conveyors, printing presses, and other high-speed machinery. Its primary function is to prevent excessive oscillation or jerking, helping to maintain smooth, stable operation of the system. The snubber roller works by applying controlled resistance or damping to the moving material or mechanical parts.

Get a Quote

Steering rollers are used to steer coils and webs, our rollers are ozone and abrasion-resistant. It is a mechanical component used to guide or control the direction of materials or machinery in various industrial applications. It is often employed in systems where precise control of material movement is necessary, such as in conveyors, printing presses, or textile machines.

The primary function of a steering roller is to ensure that the material or machine parts move in the correct direction, preventing misalignment or deviation.

Get a QuotePickup rollers used to transfer paint or chemicals from pans to the coating roller. our rollers are wear resistance and available in a variety of surface finishes. A pickup roller is a component used in various machines to grab or "pick up" materials, usually paper, film, or textiles, and feed them into a processing system. It is commonly found in devices like printers, copiers, scanners, and automated assembly lines.

The primary function of a pickup roller is to transport materials from a stack or supply into the machine. The roller uses friction to lift the material and direct it into the appropriate pathway for further processing.

Get a Quote

Slitting lines spacers are components used in slitting lines to separate the slit strips of metal. Slitting lines are machines that are used to cut metal coils into smaller strips of a desired width. The process involves passing the coil through a set of circular blades that cut the metal into strips. Spacers are used to separate the strips and prevent them from touching each other.

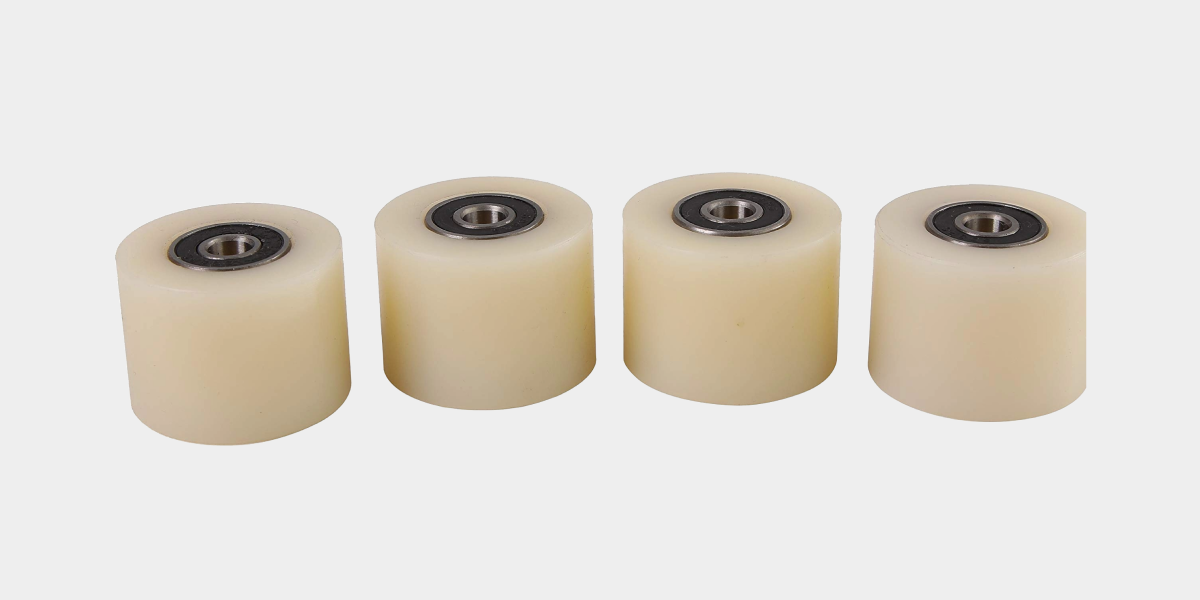

Nylon rollers are used where is height in temperature and required high abrasion and high tensile strength normally it is used in steel plants and oven conveyer lines. A nylon roller is a type of roller made from nylon, a durable and lightweight synthetic material. Nylon rollers are commonly used in various industrial applications due to their excellent wear resistance, smooth surface, and ability to handle different loads and speeds. These rollers are ideal for environments where a low-friction surface is needed for material handling, guiding, or transport.

Nylon rollers are widely used in industries like printing, packaging, material handling, and conveyors. They are often employed in conveyor systems to help move items smoothly and efficiently, reducing friction and wear.

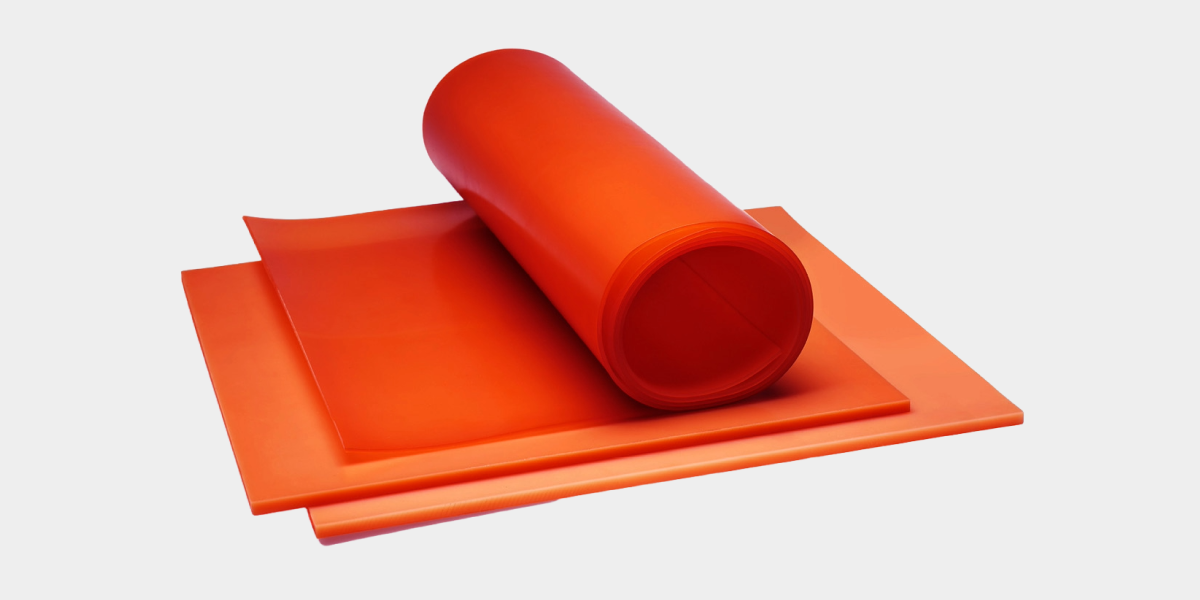

These polyurethane sheets are manufactured from thermosetting material, and therefore they cannot be reformed or reheated but they can be machined. Polyurethane components from these bases outperform products manufactured from rubber and other traditional materials.

Our company is a prominent manufacturer and supplier of high-grade steel coil saddles, it is widely used for preventing coils from skidding during transportation. we offer very high-grade material for saddles manufacturing which has properties to withstand high load wearing capacity, high temperature, and climate changes. our saddle confirms, the international standard and supports 10 to 35 tons of steel coil.

It prevents coil damage while lifting the coils for transportation. spend some money for coating the PU In Hooks saves tonnes of material.

Get a QuoteChrome rollers and TC rollers are two types of rollers commonly used in industrial applications. Chrome rollers feature a chrome-plated surface that provides excellent durability and corrosion resistance, making them suitable for use in printing, converting, and packaging processes. TC rollers, on the other hand, are made from tungsten carbide, a hard and wear-resistant material that is ideal for use in high-pressure and abrasive environments. TC rollers are known for their durability and resistance to wear, which makes them suitable for use in various industrial applications, including metalworking, woodworking, and paper processing.